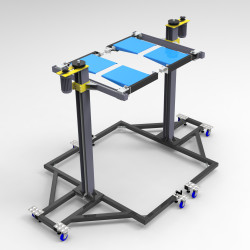

Metal Parts Cleaning Machine

enProducts™ designed, manufactured and commissioned Parts cleaning machine for cleaning metal parts of spinning motor. SS 316 Material Construction machine ensure corrosion resistant even in hight chemical erosion conditions of the parts. Diesel recycling system and compressed air clean parts that are fed to the machine.