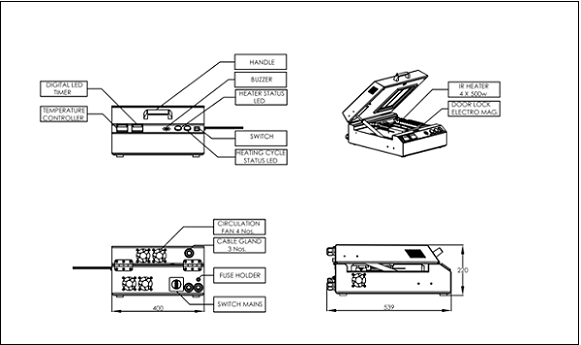

ABOUT THE SYSTEM

Heat Shrink Oven is standalone equipment designed and developed by enProducts™ for shrinking heat shrink sleeves commonly used in automotive harnesses. Highly efficient infrared heater with turbulent flow reduces power consumption considerably. Variable temperature and timing cycle makes it compatible for any type of products which requires even shrinking. Auto start and lock system ensure error free process. It’s a table top oven with inbuilt controllers. This oven supplied with custom fixture that allows multiple sleeve shrinking. Replaceable fixture allows operator to load and unload shrink sleeve with connectors outside machine, which makes this heating oven highly productive. Variable temperature and time allows this oven to be fully flexible for different type of shrink sleeve application.

Electrical Specification:

- Input Power: 1 Phase – 230 V 50- Hz, 2KVA.

- 4 x 500 W Infrared heaters.

- 24 V Controllers.

Features

- Multiple Shrink Sleeve Holder (10 Nos)

- Ceramic IR heater

- Even heating around sleeve.

- Variable Heating temperature up to 250 Degree.

- Variable cycle time.

- Auto door Lock protection.

- Auto Start.

- Cycle complete alarms and LED indication.

- Custom fixture.

- Sensor for Fixture

Shrink Sleeve Heating Oven Overview Shrink Sleeve Heating Oven