enProducts® recently successfully completed 6 Axis Industrial robotic insert molding projects with STAUBLI robotics. We were engaged in this project from concept design, Robotic model selection, Claw module design, Manufacturing and integration. This project handled 44 small components handling, 2 finished parts including the runner in 60 seconds.

Design.

enProducts® team worked closely with clients’ engineers. And have a tremendous effort to understand and align with clients’ requirements at each stage starting from concept design to the final fine-tune adjustments and improvements. Our CAD engineers have associated with the enCAD Team to build the most accurate and adaptable design.

Manufacturing.

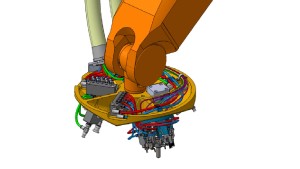

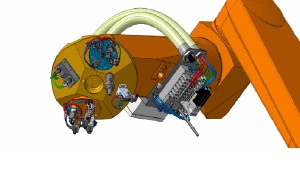

The critical part evolved to be a complex turret design for the claw design. Accuracy was the major criterion for manufacturing claw modules and gripper modules keeping the weight of the claw module to be less than 18 kg. The robot’s nominal load-carrying capacity was 28 Kg. To operate at high speed with 25-micron repeat-ability all the parts were made by CNC process to ensure exactness with the 3d model. Using the most advanced CNC 5th axis machining with high accuracy EDM process makes the overall claw module exactly perform the result as per design.

Pneumatics and Integration.

Specifically designed and configured pneumatic actuators and grippers made positive gripping of all smaller components and ensure reliability in gripping. Suction modules and vacuum generator modules are selected according to the part weight. In addition to this, a built-in referencing rod with feedback and suction holding has provided user-friendliness in referencing Mold with the robot.

Controller Integration/ Programming.

The controller has integrated with a Siemens PLC control panel with 32 I/O with Staubli controller, Euro map, Emergency, safety switches, molding machine as per schematics. Our electronic engineers closely worked with the Staubli team for robot programming.