A relay cover cleaning machine stands out as a specialized apparatus meticulously crafted for the purpose of cleansing the covers or enclosures of electrical relays. Relays are devices used in electrical systems to control the flow of electricity and are commonly found in industrial settings, power distribution systems, and control panels. Over time, relay covers may accumulate moisture and remnants of flash from the manufacturing process, necessitating a meticulous cleaning process.

The significance of thorough relay cover cleaning cannot be overstated, particularly in critical applications where the consequences of contamination or failure could be severe. To address this, our cutting-edge relay cover cleaning machine not only excels at eliminating contaminants but also possesses the unique capability to neutralize any electrostatic charges present.

In industrial environments, where precision and reliability are paramount, the reliability and safety of electrical systems hinge on the cleanliness of relay covers. The specialized cleaning mechanism ensures that not only are physical impurities effectively removed, but any lingering electrostatic charges are also nullified. This dual-action approach enhances the overall integrity of the relay covers, contributing to the longevity and optimal performance of the electrical systems they safeguard.

Investing in our relay cover cleaning machine is an investment in the reliability and safety of your electrical infrastructure. With its advanced features and dual-cleaning functionality, it stands as a testament to our commitment to maintaining the highest standards in electrical system maintenance.

Key Features:

- 60 – 80 parts cleaned per minute.

- Customizable according to requirements.

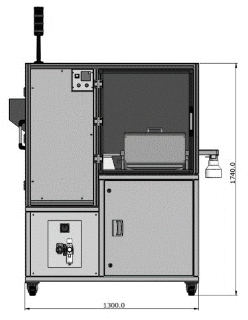

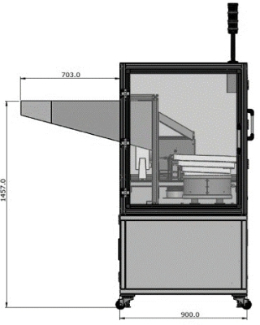

- Compact and portable.

- Rugged construction.

- Easy maintenance.

- ESD ionizer fan enabled.

Specifications:

- Input Power : 2.5 KW. 1 PH, N, E

- Weight : Approx. 450 Kg

- Operating Pressure : 6 Bar