Durability testing is the duration of time a product, part, material, or system can meet its performance requirements. e.g. lifetime span. Durability testing is generally considered a subset of reliability testing.

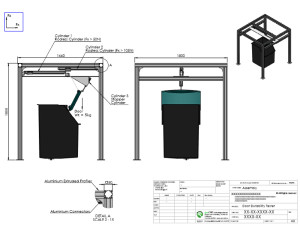

enProducts recently designed and developed a Door Durability tester for testing a newly manufactured 48″x 24″ size ice box door hinge to test its reliability, durability, and functionality in real situations. This unit is designed to accommodate two sized doors with box, with a universal easy to operate clamps.

Totally PLC controlled system counts each operation time, and sequence and stop according to the predetermined

cycle values. Machine also provided with an HMI interface for changing the set values, to retrieve test values, and to display counts of each testing. An IP 54 electronic control box with industrial harnessing and connectorization is adopted for the control unit. Best in class PLC Module from SIEMENS CPU is the core controller. For eliminating electric leakage, strict safety protocol is followed.

Machine has a Siemens HMI with easy access push button control panel which is easy to use and monitor the testing cycle counts. With test cycle history. The whole control has retentive memory hence resume cycle even after power shutdown.

We specify, design, and buy assets based on Life Cycle Cost (LCC) instead of lowest cost to buy. This means that decisions on what to buy are based on costs to buy and costs to own an asset over its economical life, instead of buying assets solely on purchase price. A world-class organization has maintenance professionals involved very early in a project. These professionals know how to perform reliability and maintainability analyses of systems and components.

As a result, complete bills of materials, training manuals, and detailed drawings are delivered according to your documented maintenance standards. Which ensure its reliability from design by choosing the best in class components from leading brands of automation.