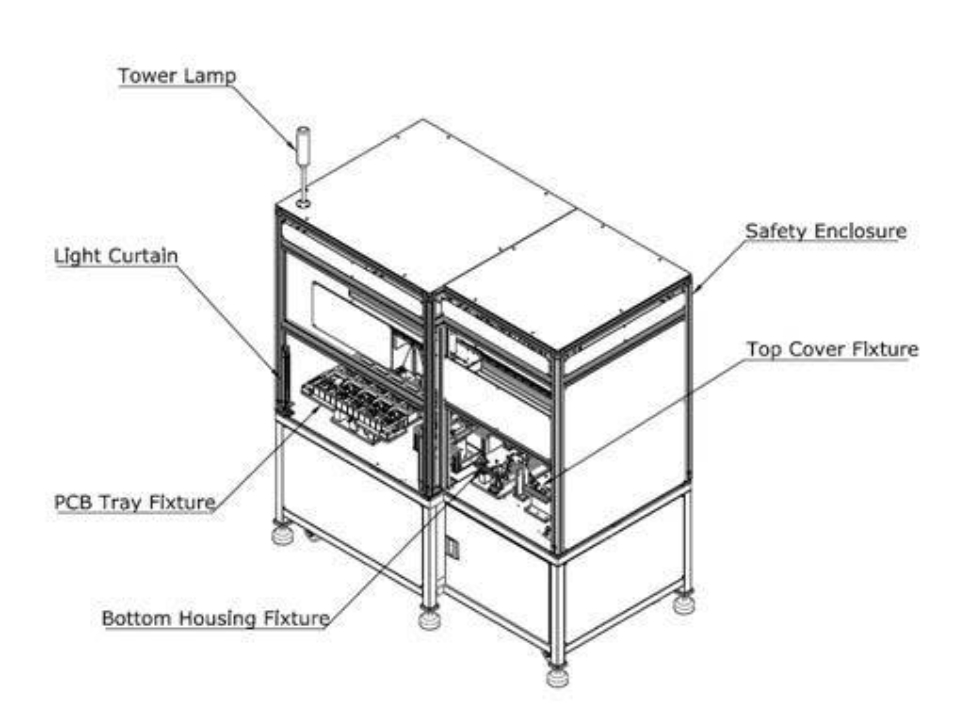

The PCB assembly machine is an automation machine developed in order to assemble the PCB to the PCB housing. The PCB is subjected to initial inspection by a vision system for detection of any type of damage or change in position, thereby ensuring proper assembly between the parts. The PCB assembly machine is integrated with a bar code scanner and the data can be stored for further access.

Key Features:

- Advanced vision system for identification of damage and position

- Vision system integrated with barcode scanning of PCB

- LCD display monitor for vision system analysis

- HMI for display of machine status

- Easy and simple operation

- Easy accessibility in case of maintenance activities

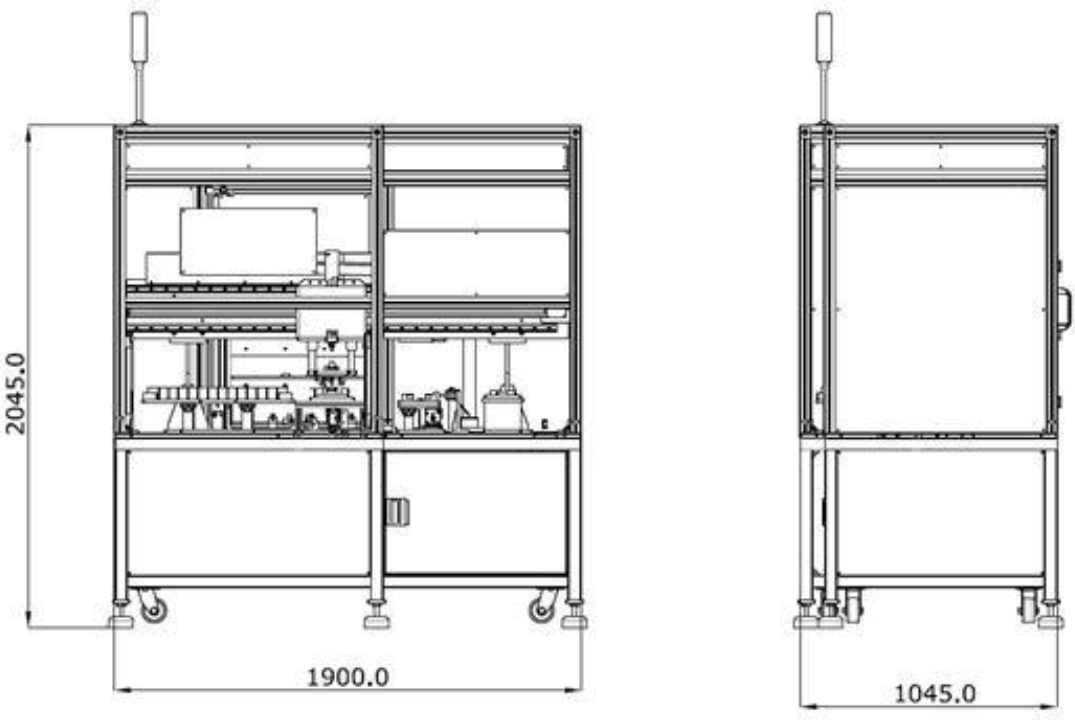

Specifications:

- Input Power : 1 Phase – 230 V 50HZ, 2KVA

- Weight : Approx. 800 Kg

- Operating pressure: 6 bar