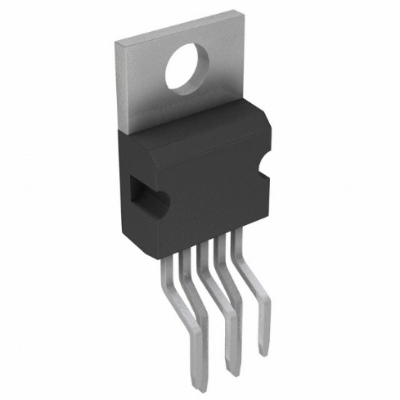

In the world of electronics manufacturing, our IC Bending Machine takes center stage as an indispensable tool, meticulously designed to simplify the lead preparation process for integrated circuits (ICs). Crafted with precision and efficiency in mind, this state-of-the-art machine brings a touch of innovation to the assembly line.

What sets our machine apart is its remarkable flexibility and accuracy, ensuring the bending of IC leads to seamlessly fit a wide range of circuit board layouts. Whether you’re dealing with DIP (Dual In-Line Package) or SMD (Surface-Mount Device) ICs, our IC Bending Machine guarantees flawless lead alignment, effectively minimizing the likelihood of soldering errors and elevating the overall quality of your electronic assemblies.

This machine is not just a technological marvel; it’s a reliable partner for electronics manufacturers aiming to navigate the complexities of IC lead bending with confidence. Its meticulous design not only prioritizes precision but also emphasizes efficiency – a crucial blend for today’s dynamic manufacturing environments.

Beyond its technical capabilities, our IC Bending Machine becomes a trusted ally for manufacturers, offering a consistent and reliable solution. The reduction in soldering errors doesn’t just enhance precision; it translates into increased productivity and reduced material wastage, aligning seamlessly with the demands of contemporary electronics production.

In essence, our IC Bending Machine is more than just a piece of equipment – it’s a cornerstone in the pursuit of excellence in electronics manufacturing. With a commitment to redefining standards in precision, efficiency, and overall quality, this machine stands as a testament to our dedication to innovation. As the industry evolves, our machine remains a human-centric force, driving success and ingenuity on every step of the assembly line.

Key Features:

- Adjustable bending parameters

- Versatile compatibility.

- Batch processing capability.

- Rugged construction.

- Easy maintenance.

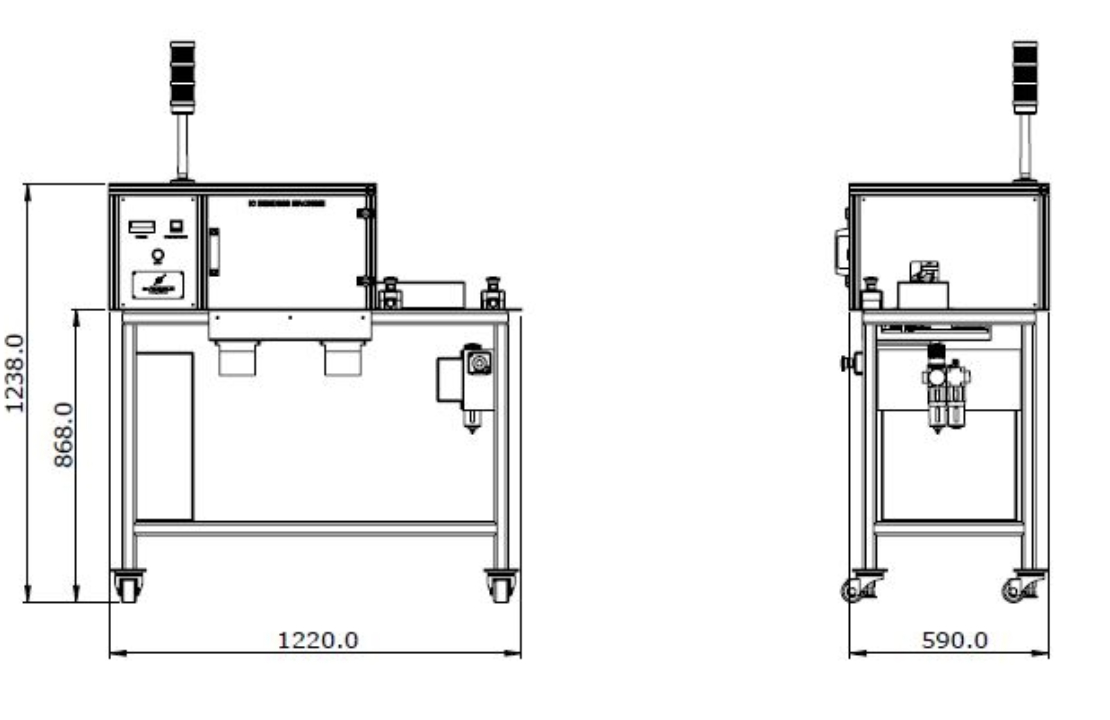

Specifications:

- Input Power : 600W. 1 PH, N, E

- Weight : Approx. 300 Kg

- Operating Pressure : 6 Bar

- Drive System: Electrical Drive