When plastic parts need to assemble into metal parts or any other material after molding, there are different methods to do so. The easiest is to glue together. Another process is to screw, and when IP is required, ultrasonic welding can be done. When it comes to the cost and effectiveness of joining together, the heat staking process is another efficient and effective way to do it in automotive parts. Such a process requires a Heat staking machine, with controlled heat and pressure.

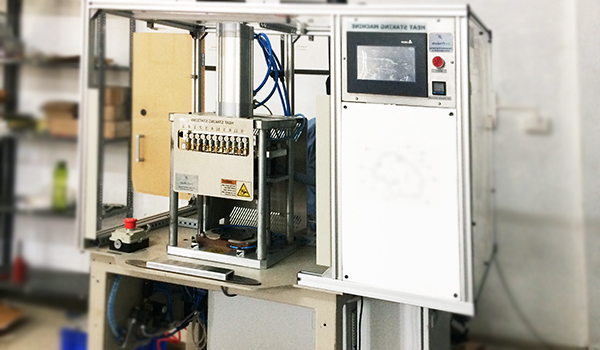

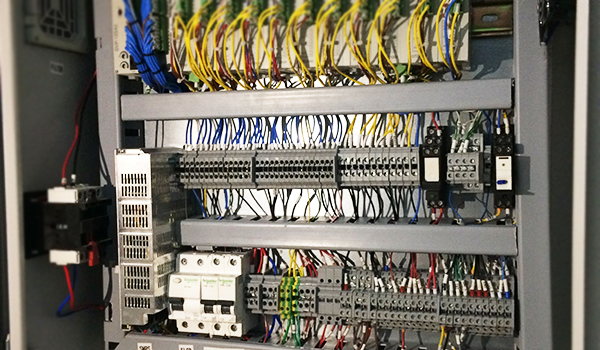

We enProducts® manufacture heat staking machines that are capable of joining plastic material with another material with a designed protrusion in the plastic and hole in the other material, similar to riveting this process is called heat staking. Our machines can be customized according to the plastic parts. Our machine is built on industrial standards with PLC and controllable temperature and other parameters.