Boiler Feed Logger was a challenging project for enProducts®, when our customer comes with such a requirement which has no one used before. One of the leading extract exporters uses different feed materials which is the input of the boiler.

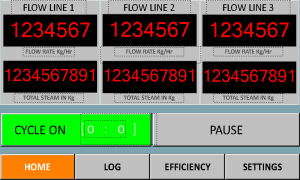

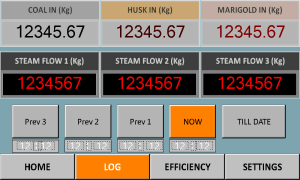

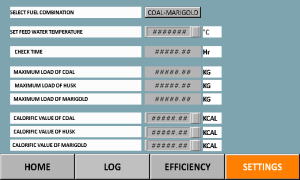

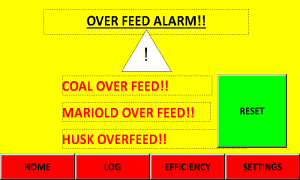

This customer was using different process waste materials like Husk, Marigold along with coal for fueling their boiler. And they had difficulty in controlling that feed inventory due to the way the input material was feeding. It was unable to monitor or control feed to the boiler. We studied this customer issue and provided a solution for identifying and controlling feed input. We also added value to this process by monitoring the overall output from the boiler. Thus the real ensuring the real-time efficiency of the control room.

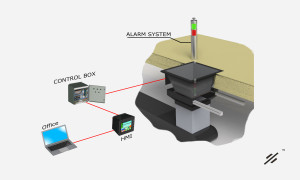

IP rated control panel with a highly reliable and accurate PLC based solution is installed in line to execute this task. We have also made all these data available on the manager’s PC which includes the following information.

- Real Time efficiency.

- Shift based input feed material quantity.

- Material wise utilization.

- Boiler output generated.

- Runtime and production cost.

This project was executed in a tight timeframe including the design and supply of mechanical components. Hopper system is installed with the help of customer contractors.