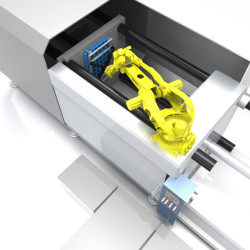

Case Study: EOL Tester with Integrated Vision Inspection

Problem A Tier-2 automotive components manufacturer was struggling with quality assurance in their final assembly line. The products — connectors and harness assemblies — were going through manual end-of-line checks that relied heavily on operator visual inspection and basic functional testing. This led to: Inconsistent defect detection High reliance on skilled inspectors Missed defects slipping[…]